- Services

- Metals (overview)

- Plastics (overview)

- CAD Design

- Rapid Prototyping

& Rapid Tooling - CNC Machining

- Finishing & Assembly

- Rubber Plaster Molding

- Precision Airset Sand Casting

- Graphite Mold Die Casting

- One-Shot Casting

- Reaction Injection Molding (RIM)

- Rapid Injection Molding

- Design for Manufacturability (DFM)

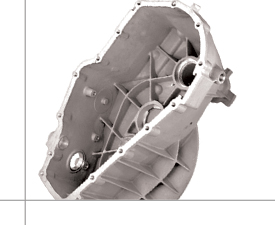

Left: automotive transmission housing.

Small engine cylinder from the airset sand casting process.

Defense application of airset sand casting.

Precision Airset Sand Castings

Precision Airset Sand Casting is a modified sand casting process that allows Armstrong RM to produce larger aluminum and zinc parts in 2-5 weeks. By using this precision sand casting method, your parts offer superior metallurgical properties in thick wall sections and superior surface finishes when compared with other sand casting techniques.

- Parts in 2-5 weeks

- Simulates larger die cast parts for appearance and properties

- Low cost tooling allows for ease of geometry modification

- Excellent production method for programs that can't justify hard tooling

- Superior metallurgical characteristics - certifications available

The advantages of the Precision Airset Sand Casting process are achieved through the use of a fine grain silica and a no-bake process. When compared to conventional sand casting and V process casting, you will see (and feel) the difference in surface finish and detail.

Precision Airset Sand Casting is a complementary process to Rubber Plaster Molding. To determine which is best for your application call us today, or send an email to sales@armstrongmold.com.

For detailed specifications, view a technical data sheet for Precision Airset Casting.

Watch Video

Interested in seeing how our Precision Airset Sand Casting process works?

Step into our moldmaking and foundry departments by clicking on the video to the right.