"Armstrong RM began with modest dreams of building a small firm of five. Today, as the company celebrates its 50th anniversary, Armstrong employs over 150 people, headed up by the family’s next generation."

50 Years of Armstrong Rapid Manufacturing

By Laura Griffiths

Published in Time-Compression Technologies

"We like to think of ourselves as a fine blend of the 14th and 21st Centuries."

The last 50 years have seen many technological milestones. In 1968, man was yet to walk on the moon, computers were enormous, and the plastics industry was about to boom. For a family business in Syracuse, NY, 1968 would mark the beginning of legacy as a leading manufacturing supplier to some of the biggest companies in the world.

Founded by John and Betty Armstrong, who came to the U.S. from Coventry, UK, where John started out as a Wood and Metal Pattern Maker apprentice, Armstrong RM began with modest dreams of building a small firm of five. Today, as the company celebrates its 50th anniversary, Armstrong employs over 150 people, headed up by the family’s next generation.

“I was 9-years-old and with my dad at the plant when the first equipment was delivered,” Peter Armstrong, President of Armstrong RM recalls. “I didn’t have a clue what it was. Today, decades later, I still see some of that original equipment as I walk around our plant.”

When Armstrong started out, the company intended to make cast molds for plastic molding, but soon got into the RIM (Reaction Injection Molding) process when a customer problem turned into an opportunity. A clothing designer came to Armstrong to produce a mannequin mold but soon struggled to find anyone to run the body forms. A short conversation with a local material supplier later and a 50-piece order for RIM polyurethane was made.

After a few successful years, it was decided that getting into the casting business, where John had started off at Sims Castings in the early 60s, would be the way to go when a sales rep showed up at the Armstrong home in Minoa with 37 aluminum casting jobs to quote for technology giant, IBM. The team can still remember the meeting in the Armstrong family living room going on until the early hours when what was thought to be an initial order for a handful of the most suitable parts ended with IBM ordering quantities of all 37.

Armstrong production

facility

Armstrong production

facility

During the 1970s, the company expanded, leasing a new facility and ramping its team up to around 75 employees. Throughout the next decade, rapid growth continued as Armstrong became a primary supplier to companies at the beginning of the telecomm technology explosion. Additional locations were sought, and a machine shop was added.

Armstrong currently boasts a state-of-the-art 100,000 square ft. manufacturing facility featuring numerous casting, molding, machining and rapid prototyping processes for prototypes and low volume metal or plastic production, along with a recently acquired space in Hingham, MA. TCT paid a visit to the new office last year where examples of handcrafted wooden models and plastic prototypes provided a clear view of how the company has evolved over the years.

“We try to utilize any technology that helps us fulfill our mission,” Paul Armstrong, Director of Marketing told TCT. “We find that many time-tested older methods like casting aluminum can provide the best path to manufacture a part especially if taking advantage of more 21st century technology in the process such as AM models, CMM inspection or CNC Machining. We like to think of ourselves as a fine blend of the 14th and 21st Centuries.”

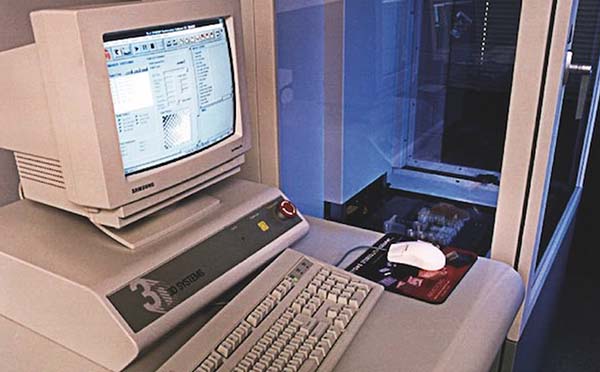

Armstrong has always been about embracing old school craftsmanship with modern technologies. In 1994, the company was the first manufacturer in New York State to purchase and utilize a 3D Systems stereolithography machine. Being an early adopter meant Armstrong spent much of the decade focusing on its rapid prototyping business, creating models for manufacturing cast injection molds in a variety of consumer related applications from Black and Decker to Whirlpool, and McDonalds.

“Installing 3D Systems equipment was significant as it was new, exciting technology that our customers were just learning about,” Peter explained. “It positioned us as an early technology leader, pulled in a lot of customer interest and was a significant advancement to improve our services and reduce lead times.”

Armstrong was an early adopter of SLA tecnology.

Armstrong was an early adopter of SLA tecnology.

Nowadays you would be hard pressed to find an area within which Armstrong hasn’t made some form of model or part, whether it’s in space on the NASA shuttle; protecting the homeland under oceans on submarines; or cast hubcaps for President Obama’s inaugural limo.

“Over the years, we have made so many interesting parts for the cutting-edge technology of the time,” Paul added. “Most recently we have been working with Rethink Robotics of Boston in developing and launching the Sawyer robot, we worked with Civiq Cityscapes on the Link NYC kiosks all over greater New York City. My favorite part we made in the early days was a cast aluminum guitar body for a local guitar maker named Jim Brunet. He gave one of his first guitars to Keith Richards of the Rolling Stones who used it that night at their concert at the Carrier Dome in front of 50,000 fans.”

By the end of the 90s, Armstrong had grown to 240 employees with sales over 20 million USD but technological shifts and major events in U.S. history, meant that by the early 2000s, the industry landscape looked very different. As Armstrong describes, “the honeymoon in manufacturing was over.” But the lean period - “lean” still meaning 150 employees - was by no means the end and as the country started to get its mojo back, so did Armstrong. The company carved itself a reputation within a highly competitive, technology driven market, which saw huge orders from those initial blue-chip customers like IBM. By 2008, Armstrong reached a high-water mark with sales close to 30 million USD.

Handcrafted wooden pattern

Handcrafted wooden pattern

Today, customers include the likes of Uber, Rethink Robotics, Medtronic and Boeing, still comprising that old school mentality with modern solutions whether making one or 1,000 parts. The company has grown from a “mom and pop” shop into a modern manufacturing facility, but there are still new challenges, particularly in exciting the next generation to get involved in manufacturing and engineering.

“Skilled labor is much scarcer as manufacturing has been perceived as a declining career path when in fact with the advent of all the new advanced manufacturing technologies the high skilled opportunities are endless,” Paul commented.

Armstrong’s motto is, “a strong future stands behind us.” There’s a history of experience, knowledge and of course, mistakes made, but Armstrong is by no means resting on its laurels. It can’t, the manufacturing industry is constantly changing and in the current age of automation and new processes coming in at a rapid rate, the team is not afraid of getting stuck into the latest technology or opportunity.

Paul concludes: “All of that drives us forward, to keep providing high quality castings and molded plastics parts as we head into our next 50 years.”